Head of the Department

Total Intake

60

Overview

The Department of Mechanical Engineering has been in existence since 2013 with the intake of 60 students. The department has excellent infrastructure by keeping on par with the latest trends. The Department is grown into a full-fledged one with well-equipped lab facilities, Infrastructure and faculty members of various specializations. The faculty members are not only committed to the teaching profession but also involve themselves in research and constantly, filing patent publish papers in conference proceedings, International and National Journals with respect to their field of specialization. The department has been producing excellent results with distinction in the university examinations consistently.

The Department provides high quality education along with discipline. The faculty members make it possible to give individual attention to the learners and to motivate them to achieve their professional goals. The curriculum structure of the department is designed to meet the present day requirement of Industries and corporate sectors. The interaction between the staff and students is excellent and all the laboratories are well equipped as per the requirements of the curriculum.

VISION

To excel in Mechanical engineering by producing skilled, innovative engineers who address societal challenges and develop impactful solutions through research, collaboration, and practical applications.

MISSION

Teaching Faculty

The pillars of Mechanical Engineering

Dr. Suresh Premil Kumar R

Senior Professor Principal

Dr. Sivaprakash M

Professor Head

Dr. Jenix Rino J

Associate Professor Director

Dr. Brabin Nivas M L

Associate Professor

Mr. Ajith kumar S

Assistant Professor

Mr. RajKumar S.R

Assistant Professor

Mr. Bravin Daniel E

Assistant Professor

Mr. Vijayan P

Assistant Professor

Mr. Manikandan N

Assistant Professor

Mr. Rakhesh I P

Assistant Professor

Mr. Sarasa Kumar K

Assistant Professor

Mr. Ajai L K

Assistant Professor

Mr. Sujin M

Assistant Professor

Mr. Jein Sam Dhas R

Assistant ProfessorNon-Teaching Faculty

The supporting hands of Mechanical Engineering

Arunachalam L

Laboratory Instructor

Shaju E S

Laboratory InstructorPlumbing Work

Wood Work

Welding Work

Basic Machining Work

Assembly Work

Sheet Metal Work

Foundry Work

CADEM Centre is established to impart practical experience in handling 2D drafting and 3D modeling software. To understand the features of CNC Machine tool and to know the application of various CNC machines like CNC lathe, CNC Vertical Machining centre. To give exposure to software tools needed to analyze engineering problems. To expose the students to different applications of simulation and analysis tools. Students of Mechanical Engineering program use the center for laboratory courses like Computer Aided Machine Drawing, Computer Aided Design and Computer Aided Manufacturing lab, Simulation and Analysis laboratory and Interpersonal skill & listening and speaking laboratory as per their curriculum. They also use this centre for the preparation of Technical Seminar laboratory, mini project and main project.

Facilities

This laboratory is used to supplement the principles taught in the theory courses like kinematics of Machinery and Dynamics of Machinery to make understand how certain measuring devices are used for dynamic and kinematics testing.

Facilities

This lab is to study the applications of the conservation laws to flow through pipes and hydraulic machines. To understand the importance of dimensional analysis. To understand the importance of various types of flow in pumps and turbines. Upon Completion of this lab, the students can able to have hands on experience in flow measurements using different devices and also perform calculation related to losses in pipes and also perform characteristic study of pumps, turbines etc.,

Facilities

This lab is to study and practice the various operations that can be performed in lathe, shaper, drilling, milling machines etc., and to acquire knowledge on various basic machining operations in special purpose machines and its applications in real life manufacture of components to equip with the practical knowledge required in the core manufacturing industries. The laboratory courses Manufacturing Technology-I and Manufacturing Technology-II will be taught using this laboratory.

Facilities

This laboratory is to familiarize the students with different measurement aids and equipments and its use in the industries for quality inspection.

Facilities

This lab is to familiarizing the students with the method of programming the microprocessor and also with the design, modeling & analysis of basic electrical, hydraulic & pneumatic systems which enable the students to understand the concept of mechatronics.

List of Equipments

To supplement the theoretical knowledge gained in the theory courses like Engineering Metallurgy and Strength of Material with practical testing for determining the material behavior and strength of materials under externally applied loads. This would enable the student to have a clear understanding of the design for strength and stiffness.

Facilities

This laboratory is to study the value timing, port timing- diagram and performance of IC Engines. To Study the characteristics of fuels/Lubricates used in IC Engines. To study the Performance of steam generator/ turbine. To study the heat transfer phenomena and predict the relevant coefficient using implementation. To study the performance of refrigeration cycle / components. This lab consists of separate Steam an IC engines lab, Hear Transfer Lab.

Facilities

Board of Studies Members

| # | Name | Designation | institution | Role |

|---|---|---|---|---|

| 1 | Dr. F. Michael Raj | Professor & Head | SMCE | Chairman-BoS |

| 2 | Dr. N. Shenbaga Vinayaga Moorthy | Professor, MECH | Anna University, Regional Campus, Tirunelveli - 627 007 | University Nominee |

| 3 | Dr. V. Mago Stalany | Associate Professor, Fire Technology and Safety Engineering | NICHE, Kumaracoil, Thuckalay | Subject Expert Member (External) |

| 4 | Dr. R.S. Jayaram | Associate Professor, MECH, | Amrita College of Engineering and Technology, Nagercoi | Subject Expert Member (External) |

| 5 | Mr. A. Anesh Darrel | Executive Director Darrels AM Research and Reverse | Engineering Labs Private Limited, Nagercoi | Industrial Expert |

| 6 | Mr. S. Jenish Rahul | Executive Engineer, R&D | Conserve Solutions,Chennai | Alumni |

| 7 | Dr. R. Suresh Premil Kumar | Professor & Principal | SMCE | Member |

| 8 | Dr. J. Jenix Rino | Associate Professor & Director | SMCE | Member |

| 9 | Dr. M. Sivaprakash | Professor | SMCE | Member |

| 10 | Dr. C. Dhayananth Jegan | Associate Professor | SMCE | Member |

| 11 | Dr. M. Abeens | Associate Professor | SMCE | Member |

| 12 | Dr. M. L. Bravin Nivas | Associate Professor | SMCE | Member |

| 13 | Mr. S. R. Rajkumar | Assistant Professor | SMCE | Member |

| 14 | Mr. E. Bravin Daniel | Assistant Professor | SMCE | Member |

| 15 | Mr. S. Ajith Kumar | Assistant Professor | SMCE | Member |

BoS Minutes

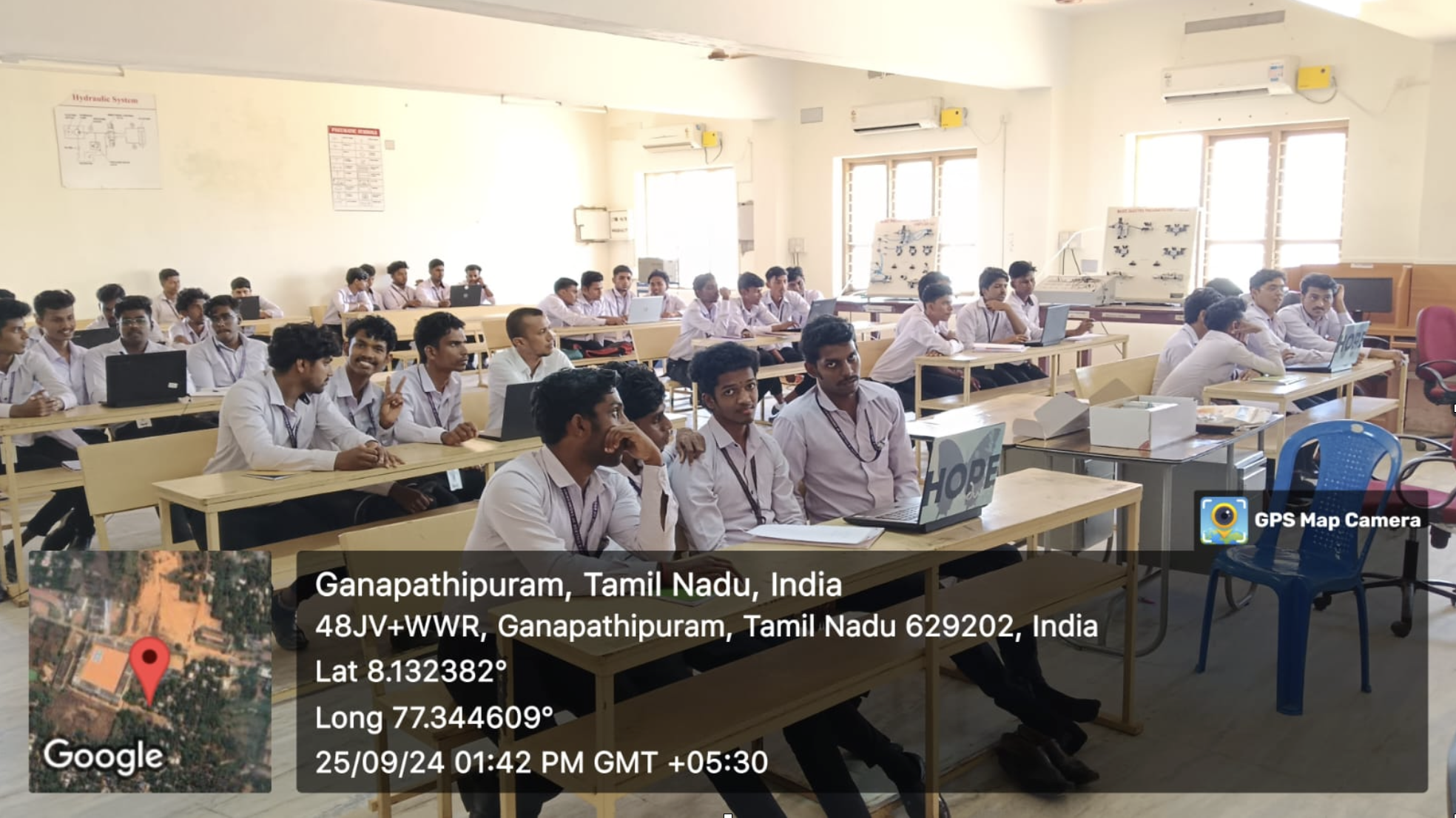

Innovation in Teaching Learning

LMS

Achievements

Outcome

Programme Outcomes

Program Specfic Outcomes

On successful completion of the Mechanical Engineering Degree programme, the Graduates shall exhibit the following:

PROGRAM EDUCATIONAL OBJECTIVES (PEOs)

OBE MANUAL

Academic Calender

Testimonials

Words from our Alumni